Product description

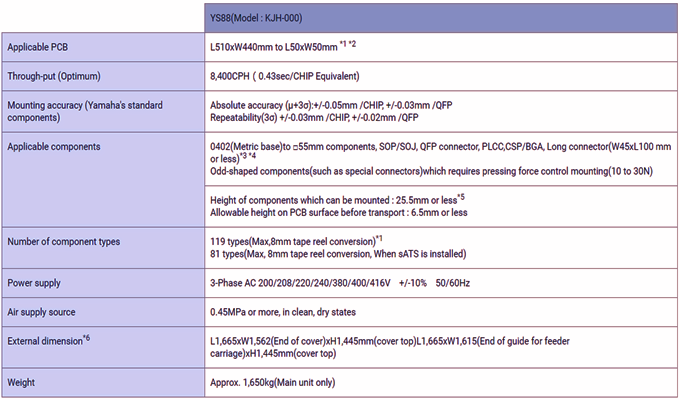

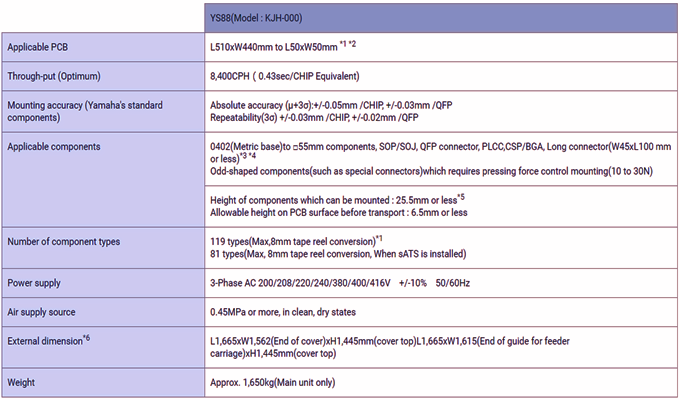

The YS88 is equipped with 3 fully independent servo-controlled Flying Nozzle Change (FNC) heads, each carrying up to 6 nozzles. It delivers high-end performance with chips, ICs and odd form components. Not only does it offer placement rates up to 8.9k components per hour with a placement accuracy of 30 micron for ICs and QFPs, but it also handles an extremely wide component range as tall as 25.5mm. Precision force control allows optimal handling of press-fit through-hole connectors with forces up to 30N.

By holding up to 119 feeding positions, the YS88 offers the ultimate in changeover flexibility.

Handles a super-wide range of components from 0402 chips to W45xL100mm or less components and with long connectors

Handles components with heights up to 25.5mm

Simplified pressing force control from 10 to 30N

+/-30μm QFP mounting absolute accuracy and

+/-20μm QFP repeatability in full time operation

8,400CPH(0.43sec/CHIP Equivalent : optimum condition)mounting capacity

Applicable to large size PCB(L510mm x W460mm)

The standard YS88 comes with many software and hardware features that improve product quality, increase production efficiency and reduce maintenance, including:

It is varied by the combination layout together with sATS / dYTF etc.

For information on "2 stages push-up spec.", please consult us separately.

A preliminary arrangement is necessary when a side-view camera is installed.

When handling long connectors and large sized components, about the eccentric offset values and the rotation angle, please consult us separately.

22.5mm or less when the side-view camera is installed.

This dimension does not include the projection.

Main benefits

Intelligent electrical feeders

Z-Servo controlled placement heads for accurate stress-free component mounting

Automatic board width and thickness adjustment for fast changeover

Automatic nozzle cleaning station

Automatic temperature feedback compensates for temperature variations

Fiducial recovery function that eliminates the need to remove and clean the PCB

Feeder indicators that simplify setup and reduce feeder setup

Double board support system that decreases board transfer time

Force control

Tape cutting