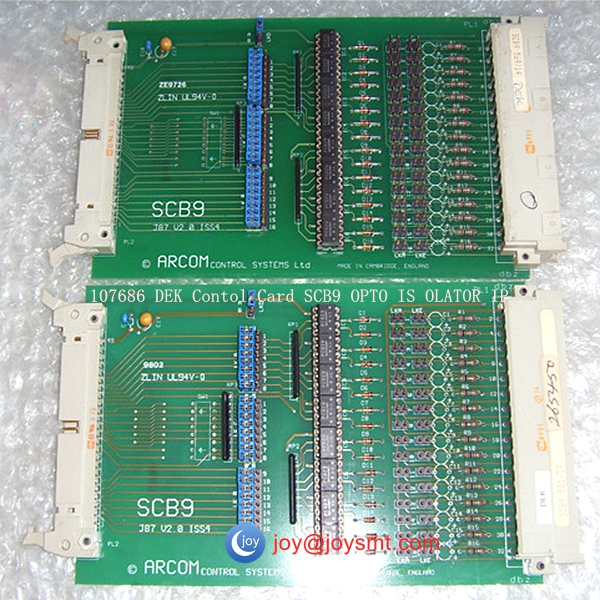

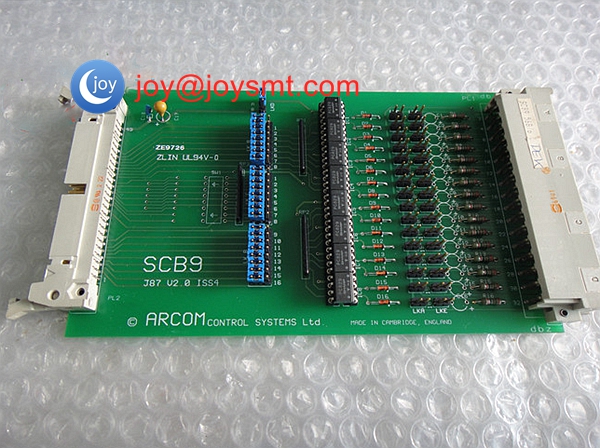

107686 DEK Contol Card SCB9 OPTO IS OLATOR IP

First, the printed circuit board graphic alignment

Through the printer camera, the optical positioning point (MARK point) of the substrate and the stencil on the workbench is centered, and then the X, Y, and Θ of the substrate and the stencil are finely adjusted to make the substrate pad pattern and the stencil opening. The graphics are completely coincident.

Second, the angle of the scraper and the circuit board during printing

The smaller the angle between the scraper and the stencil, the greater the downward pressure, the easier it is to inject the solder paste into the mesh, but it is also easy to squeeze the solder paste onto the underside of the stencil, causing the solder paste to stick. Generally 45~60 °. Currently, most automatic and semi-automatic printing presses use 60°.

Third, the amount of solder paste applied to the smt solder paste printing machine (rolling diameter of solder paste)

1. The rolling diameter of solder paste is suitable for ≈h≈10~15mm. 2. The rolling diameter ∮h is too small to cause solder paste to be printed and the amount of tin is small. 3. The rolling diameter ∮h is too large, too much solder paste is in When the printing speed is constant, it is easy to cause the solder paste to fail to form a rolling motion, the solder paste cannot be cleaned, resulting in poor printing release, poor solder paste after printing, etc.; and excessive solder paste is exposed to the air for a long time. The quality of the solder paste is unfavorable. 4. During the production, the operator visually inspects the amount of solder paste on the stencil every half hour, and moves the solder paste outside the squeegee stroke on the stencil to the stencil every half hour. The solder paste is evenly distributed within the stroke of the blade, but it cannot be shoveled into the opening of the stencil.

Fourth, the pressure of the scraper when the smt solder paste printing machine works

The blade pressure is also an important factor affecting the printing quality. The blade pressure actually refers to the depth of the blade falling, the pressure is too small, the blade does not adhere to the surface of the steel mesh, so it is equivalent to increase the printing thickness. In addition, the pressure is too small, the surface of the steel mesh will remain. A layer of solder paste can easily cause printing defects such as printing and bonding (bridge).

?Fifth, the printing speed of smt solder paste printing machine

1. Since the speed of the scraper is inversely proportional to the viscosity of the solder paste, the speed is slower when there is a narrow pitch. The speed is too fast, the time for the scraper to pass through the opening of the steel mesh is relatively short, and the solder paste cannot fully penetrate into the opening. In the middle, it is easy to cause printing defects such as insufficient solder paste or missing printing.

?2. There is a certain relationship between the printing speed and the blade pressure. The descending speed is equivalent to increasing the pressure. Appropriately reducing the pressure can improve the printing speed.

3. The ideal scraper speed and pressure should be just scraping the solder paste from the surface of the steel mesh.

?Six, smt solder paste printing machine working gap

The printing gap is the distance between the steel mesh and the PCB, which is related to the retention of the solder paste on the PCB after printing.

7. Separation speed of stencil and PCB when smt solder paste printing machine works

After the solder paste is printed, the instantaneous speed of the steel mesh leaving the PCB is the separation speed, which is the parameter related to the printing quality. It is the most important in the dense pitch and high-density printing. The advanced printing machine has its steel mesh leaving the solder paste pattern. 1 (or more) a small dwell process, ie multi-stage demolding, which guarantees the best printing.

When the separation speed is too large, the sticking force of the solder paste is reduced, and the cohesive force of the solder paste and the pad is small, so that some solder paste adheres to the bottom surface of the steel mesh and the wall of the opening, causing printing defects such as less printing and tin collapse. The separation speed is slowed down. When the solder paste has a large viscosity and a large cohesive force, the solder paste is easily separated from the stencil opening wall and the printing state is good.

Eight, smt solder paste printing machine cleaning mode and cleaning frequency

Cleaning the bottom of the steel mesh is also a factor to ensure the quality of the printing. The cleaning mode and cleaning frequency should be determined according to the conditions of solder paste, stencil material, thickness and opening size. (Set dry cleaning, wet washing, reciprocating, wiping speed, etc.)

188988 rising table motor

188962 BOM^MOTOR^DRIVE^PRINT CARRIAGE

140737 rising table servo motor

140737 RISING TABLE SERVO MOTOR

140375/76/77 ACTUATOR MOTOR

186358/59/60 ACTUATOR MOTOR

185463 DESC:ACTUATOR^STEPPER^CHASE^ALIGNMENT

160457 cluch

183388 in or out pcb sensor

188317 BOM^LOOM^CAMERA CARRIAGE SIGNALS

193409 NEXTMOVE ES USB 6 STEP CONTROLLER(TXT)

165675 CYLINDER 4 STROKE 20 BORE ( TXT )

157729 rear rail motor loom assemble

181229 BOM^LOOM & MOTOR^CONVEYOR

160422 SPEED UP REAR RAIL MOTOR AND LOOM ASSEMBLY BOM

160418 SPEED UP FRONT RAIL MOTOR AND LOOM ASSEMBLY BOM

181452 BOM^PAPER CLEAN MOTOR

DEK Part 193377 boRAD STOPper

DEK Part 193408 1394 cable

DEK Part 5157438 CLAMP BORAD

DEK Part X3 X4EUROSTEP CONTROLLER RS485 16MHZ

DEK Part 145015 X1 X2EUROSYSTEM CONTROLLER RS485 16MHZ EA

DEK Part 160903 VISION CARD(8100L)

155827 COGNEX 8100M CARD (SPARES - NO LICENCE)

160555 SMPSU,650W WIDE RANGE I/P

191088 183390 BOM^SOLVENT PUMP^USC

160903 8100l cognex vision card

114025 CARD FO SERVO MOTOR

DEK Part 137516 CLAMP Board

DEK Part 137519 board clamper assy

190130 KEYBOARD^^USB^TRACKBALL INTEGRATED

DEK Part 181009 CPU BOARD

DEK Part 137325 486 CPU BOARD

DEK Part 145009 VISION CARD

DEK Part 185512 DUAL STEPPER CARD

185020 NEXT MOVE ES INTERFACE CARD

142253 CAN CONTROL CARD (MULTIMOVE) IO ( TXT )

DEK Part 191650 CAMERA SENSOR

DEK Part 156039

160723 CENTRE SECTION BOARD AT RIGHT B'GND SUP. OPTO

160721 CENTRE SECTION BOARD AT LEFT B'GND SUP. OPTO

191103 RISING TABLE MOTOR CONTROLLER

DEK 193409 CONTROL BOARD CONTROLLER

DEK CAMERA 133828

DEK CAMERA 145016

DEK CAMERA 145550

DEK CAMERA 145550,181062

DEK CAMERA 155826 (new)181322

DEK CAMERA 181056

DEK CAMERA 181062

DEK CBA40 GRAPHITE CAMERA 191640 8008629

DEK CBA40 CAMERA

DEK CBA40 GOLD CAMERA 191012 8008632

DEK CBA40 GRAPHITE CAMERA 191010 8008629

DEK CBA40 GRAPHITE CAMERA 198040 8012979

DEK CBA40 GRAPHITE CAMERA 8008629

DEK CBA40 GREEN CAMERA 191011 8008630

DEK CBA40 GREEN CAMERA 191641 8008630

DEK CBA40 GREEN CAMERA 198041 8012980

DEK CBA40 GREEN CAMERA 198811 8008630

DEK CBA40 HAWKEYE 1200 CAMERA 191644 8008634

DEK CBA40 HAWKEYE 1700 CAMERA 198044 8012983

DEK CBA40 HAWKEYE 400 CAMERA 191643 8008633

DEK CBA40 HAWKEYE 750 CAMERA 198043 8012982

DEK CBA40 HAWKEYE CAMERA 191013 8008633

DEK Part 191643 24v CAMERA

DEK Part 181322 DEK ela camera

DEK Part 198043 DEK I camera

DEK Part 198041 DEK I camera (205745)

DEK Part 198041 DEK green camera 205711

DEK Part 191641 DEK I camera

DEK Part 191643 DEK I camera 12v

DEK Part 119673

DEK Part 158982 plate snugger base variable th

DEK Part 178002 plate snugger foil-less 250 lon

DEK Part 156458 STRAIN GAUGE BEAM, BOM WITH FEEDBACK

DEK Part 155870 TYPHOON LOAD CELL LOOM BOM

DEK Part 112246 photo sensor

DEK Part 153073 DEK TORQUE AMP ASSEMBLY BOM ( TXT )

DEK Part 155510 DUAL STEPPER CARD ( TXT )

DEK Part 114025 EUROAMP 10 CARD UL

DEK Part 155506 SERVO STEPPER DRIVE BACKPLANE PCB ASSY ( TXT )

DEK Part 155518

DEK Part 160947 ATOM PC BOARD (COMPLETE)( TXT )

DEK Part 181516 ADVANTECH BP W_250W PFC PSU (TXT)

DEK Part 155945 BOM OF M24 DC POWER SUPPLY MODULE

DEK Part 160555 SMPSU, 650W WIDE RANGE I-P (FASTON TERMS) (TXT)

DEK Part 181229 BOM^LOOM & MOTOR^CONVEYOR^ (TXT)

DEK Part 157731 REAR RAIL MOTOR & LOOM ASSEMBLY

DEK Part 156918 RAIL MOTOR & LOOM ASSEMBLY

DEK Part 155692 MOVING RAIL LOOM BOM(inf)

DEK Part 158921 CYLINDER^PNEUMATIC^COMPACT^12X10

DEK Part 140454 MOVING RAIL STEPPER BOM ( TXT )

SMT DEK VISION Y AXIS SERVO MOTOR 185003 BG65X50-CI

DEK Part 160422 SPEED UP REAR RAIL MOTOR AND LOOM ASSEMBLY BOM

DEK Part 160418 SPEED UP FRONT RAIL MOTOR AND LOOM ASSEMBLY BOM

DEK Part 140472 RAIL MOTOR & LOOM ASSEMBLY

DEK Part 140988 MOVING RAIL STEPPER BOM ( TXT )

DEK Part 155804 BOM^STEPPER MOTOR^FRONT SQY(TXT)

DEK Part 155806 BOM^STEPPER MOTOR^REAR SQY(TXT)

DEK Part 109239 PHOTO SENSOR, SUNX

DEK Part 140737 MOTOR RISING TABLE

DEK Part 160708 RISING TABLE SERVO MOTOR ( TXT )

DEK Part 133129 TABLE LIFT MOTOR

DEK Part 165675 BLUE U S C LIFT CYLINDER REPLACEMENT

602162*2 BLUE U S C LIFT CYLINDER REPLACEMENT

DEK Part 146111 USC SOLVENT SOLENOID VALVE LOOM BOM ( TXT )

DEK Part 165670 USC SOLVENT SOLENOID VALVE LOOM BOM ( TXT )

DEK Part 165432 SOLENOID VALVE 3 PORT 2 POSITION (SMC)

DEK Part 165431 SOLENOID VALVE 5 PORT 2 POSITION (SMC)

DEK Part 107850 bord stoper

DEK Part 160077 MULTIMOVE CAN I/O CARD ( TXT )

DEK Part 181062 green Camera

DEK Part 181379 Dual stepper SMT

DEK Part 185311 Cosel600W 48V SW SW/Mode CPK600PSS48

DEK Part 188285 Bom Stepper motor " front " SQY ( TXT )

If there is no matching model of DEK Parts,pls contact us directly.

JOYSMT have good source & large stocks for major brand SMT Parts and Equipment.

Such as SMT nozzle | nozzle holder | nozzle shaft, SMT feeder|SMT feeder parts|Feeder calibartion jig,

Laser ,Sensor, Servo Motor, Servo Driver, Controller Board Card, Solenoid valve,Ejector, Ball screw,

SMT Belt, Cable, SMT Filter, SMT consumable Material etc.