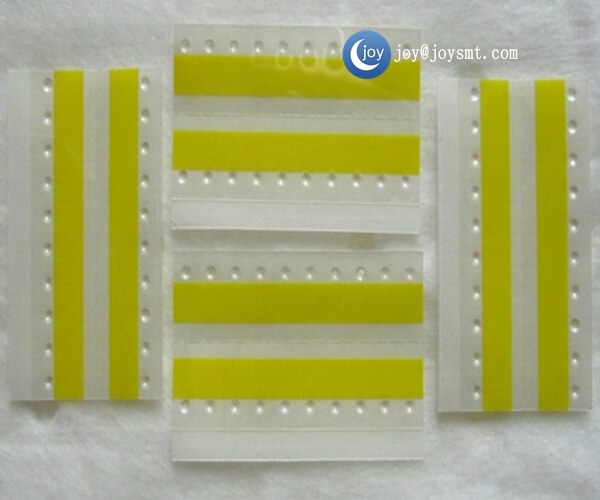

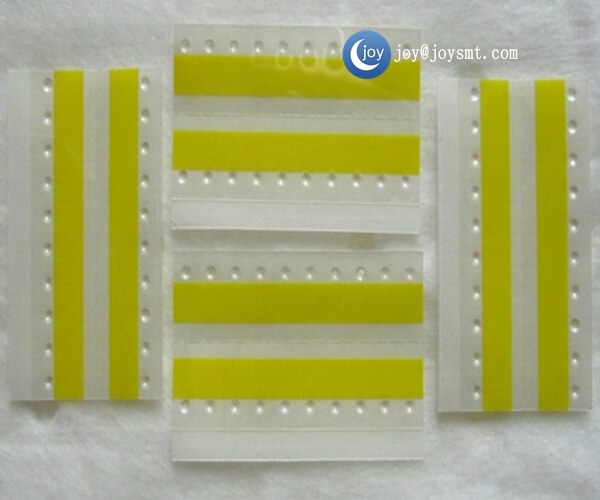

Analysis the whole production of process smt splice tape

Silk screen (or dispensing) ----- mount (curing) ---- Reflow ---- cleaning ---- testing ----- rework

Silk screen: its role is to paste or paste plastic Leakage printed on the pad to the circuit board, in order to

prepare the welding components. The equipment used for the screen printing machine

(screen printing machine), smt in the belt with the forefront of the production line. In this case,smt splice tape.

Dispensing: It is the glue drops to a fixed position on the circuit board, its main role is to be

fixed to the circuit board components. The equipment used for the dispenser, smt is located in the

forefront of the production line or testing equipment behind.

In this case,Placement: The role of surface mount components is accurately installed to the circuit board fixed

position. The equipment used for the placement machine, smt with the production line in the back of the screen

printing machine.

Curing: its role is to melt patch glue, so that the surface assembly components and circuit boards firmly bonded together.

The equipment used for the curing furnace, smt is located in the production line with the placement

machine in the back.

Reflow soldering: its role is to solder paste to melt, so that the surface assembly components and

circuit boards firmly bonded together.

The equipment used for the reflow furnace, smt is located in the production line with the placement

machine behind.

Cleaning: The role of the circuit board assembly is harmful to the human body above the welding

residues such as flux removed.

The equipment used for the cleaning machine, the location can not be fixed, can be online, or not online.

Detection: The role of the assembled circuit board for welding quality and assembly quality testing.

The equipment used is a magnifying glass, microscope, on-line tester (ICT), flying probe tester, automatic

optical detection (AOI), X-RAY detection system, functional tester. Location according to the detection

needs, can be configured in the production line where appropriate. Rework: Its role is

to detect the failure of the circuit board rework. The tools used for the iron, rework stations.

Configured anywhere in the production line.