Product description

JUKI KE-2060 Placement machine Features and price :

Joy Technology can provide used placement machine juki KE2060,with good condition and cheaper price,

The price of juki KE2060(2010 year)is only USD 39800.

The ultra-flexible KE-2060 can place a wide range of components from 0603 and ICs, to odd-form, all at a high rate of speed.

12,500CPH:chip (laser centering/effective tact)

1,850CPH: IC (vision centering/effective tact), 3,400CPH with MNVC option.

One multi-nozzle laser head (4 nozzles) plus one high resolution head (1 nozzle)

from 0603 (0201) to 74mm square components or 50×150mm

0402 (01005) option factory installed.

Vision centering system (featuring bottom, side, and back lighting, ball recognition and split recognition)

SMT placement machine in addition to the corresponding IC or complex shape of the opposite sex components, but also has a small component of the high-speed placement capability. At present, multifunctional equipment in China has been welcomed, we have a lot of customers are saying that now the processing time, do nothing can be specific, in order to survive them whether it is LED or PCB patch, they will undertake, so in the The multi-function device in the field of patch has become the key.

The choice of second-hand placement machine customers to be truly customers, second-hand placement machine low cost, new equipment can do things we can do the machine, so for us, choose second-hand The customer is wise.

1.Production arrangement starts only after receipt of P/O for E size board.

2.Effective tact: The chip placement speed indicates an estimated value obtained when the machine places 400 1005-chips all over an M size board.

(CPH=number of components placed for one hour)

3.Estimated value when using MNVC and picking up components simultaneous with all nozzles.

4.In addition to matrix tray changer, max 110.

5.Please ask for details on 0402(01005) placement.

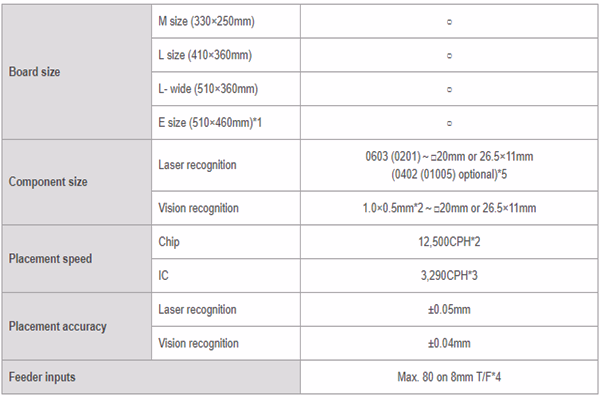

Component size Laser recognition 0603 chip (inch 0201) chip ~ 33.5mm square element

Image recognition 1.0 × 0.5mm * 2 ~ 74mm square element or 50 × 150mm (0402 (English 01005) chip requires option) * 7

Component Mount Speed Chip Components 12,500CPH * 3 IC Components 1,850CPH * 3 * 3,400CPH * 5

Component Mounting accuracy Laser recognition ± 0.05mm Image recognition ± 0.03mm (± 0.04mm when using MNVC (optional)

Up to 80 kinds of component placement (converted to 8mm) * 6

Note:

1.E size of the substrate placement machine for the production after ordering

2. When using a high resolution camera (optional)

3. Actual efficiency: Chip placement speed is the M-size substrate on the whole surface mount 400 1608 components when the conversion value IC component placement speed is M-size substrate on the whole surface mount 36 QFP (100-pin or more ) Or BGA (256 balls or more)

4. (CPH = average 1 hour of the number of mounting components)

5. Conversion value for matrix tray tray supply.

6. Use MNVC (optional), the total suction at the same time when the conversion value

7. Use multi-layer pallet changers up to 110 varieties.

JUKI JUKI 2000 series placement machine features are summaried as follows:

(1) The basic philosophy of supporting the most advanced high-density placement is "faster and more accurate" to achieve a unique technology for high-density, high-precision placement.

A. High production performance:

High Rigidity Rack: Increases the rigidity by 40% rigidity by integrating the Y-axis racks, resulting in a significant improvement in vibration performance, resulting in a 20% increase in actual placement efficiency.

High precision:

Dual-drive XY & stand-alone mounting head: For the XY unit, JUKI's fully developed AC servo system and linear encoder system are fully closed-loop control. Respectively, the X-axis Y-axis dual-motor drive, can be free from dust and temperature effects of high-speed and high-precision placement. In addition, each nozzle has a completely independent AC servo control for the upper and lower movement of the mounting head, and the height of each nozzle can be precisely controlled. Moreover, each nozzle is attached to different angles, the nozzle does not affect each other.

b.Z / θ axis independent control: the movement of each nozzle up and down (Z axis), rotation (θ axis) by the independent AC servo motor control. So that the nozzle can not be easily affected between the precise control

B. Correspondence:

Corresponding to FPC: the use of strong new OCC lighting, corresponding to FPC (flexible printed circuit board). By combining the refractive illumination, the corresponding ability of the identification of the substrate mark is further improved.

C. high quality:

Vacuum placement technology: JUKI original vacuum damage automatic suction function, can prevent the assembly near the components, solder flying

(2) laser recognition technology

JUKI's unique technical support for the future of high-density placement of the indispensable quality

A. High precision, high mounting:

High speed uniform identification: the top of the placement of the laser sensor with a high resolution, by reading the laser light components formed by the shadow, identify the location and angle. In the placement of the location to the shortest distance in the mobile to achieve uniform recognition, to achieve a high speed, high precision placement of chip components and SOP and other small components.

B. High stability:

Deviation of components has a strong ability to identify: laser recognition is mainly from the front side to capture the shape of the components, which can reduce the chip components of the electrode shape and color and other unstable factors to ensure stable and high accuracy of identification. C. Reduce bad rate:

Use the component inspection function to improve the quality of the placement: the use of laser recognition can be installed before the screen through the screen to monitor the absorption of components, can prevent the air pressure can not identify the bad parts of the bad paste. Advanced post-mount component check-in and check-in function to reduce bad stickers.

(3) image recognition:

JUKI's separately developed component identification system uses both laser recognition and image recognition (reflection recognition and identification)

A. Correspondence:

Image recognition technology: According to the shape of the component, size, material properties, etc., can be used to adapt to the chip components of high-speed placement of the laser recognition system and with high versatility of image recognition. In addition, the corresponding corresponding to the various components of the corresponding shape of the corresponding nozzle, universal image system, etc., to further play, improve the corresponding capacity components.

Universal Image System: This is a versatile image system that can flexibly correspond to evolving special-shaped components. At the time of data compilation, the data input can be further simplified and the function is more complete at the part of the preview screen, the confirmation of the part and the overall confirmation, the edge of the outline recognition element, and the confirmation of the corner.

B. High production performance:

MNVC (Multi-Nozzle Vision Centering): This is a versatile image system that can flexibly correspond to evolving isoforms. At the time of data compilation, the data input can be further simplified and the function is more complete at the part of the preview screen, the confirmation of the part and the overall confirmation, the edge of the outline recognition element, and the confirmation of the corner.