Product description

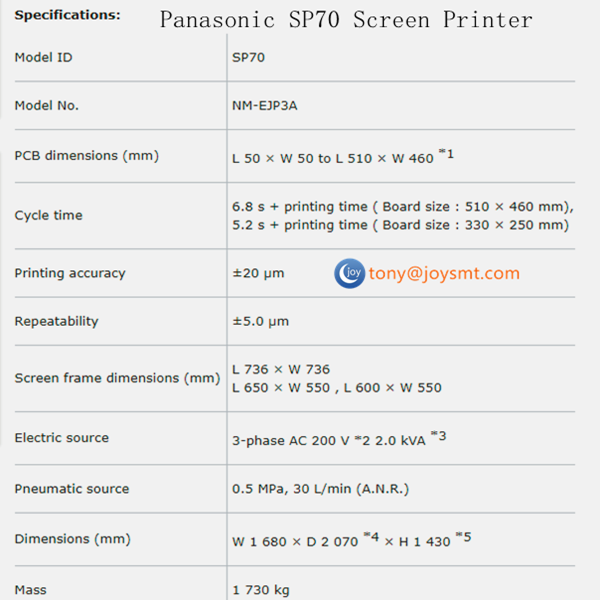

Panasonic SP70 Screen Printer|SMT Machine

1: Applicable PCB sizes: max. L 580 mm x W 508 mm

2:Compatible with 3-phase 220 / 380 / 400 / 420 / 480 V

3:Including blower and vacuum pump

4:Handle external dimension

5:Excluding monitor and signal tower

Values such as cycle time and accuracy may vary depending on operating conditions.

Ultra-high accuracy screen printing

Panasonic's SP70 screen printer is designed for both high- and low-volume manufacturers who require ultra-high printing accuracy. PCBs up to 580 x 508mm are processed in a smaller footprint than previous SP-series printers.

The SP70 supports lead-free soldering and features an advanced hybrid squeegee that delivers high quality, stability, and fast filling with quick changeover.

FURTHER PURSUING OF HIGH QUALITY PRINTING WITH "THE CORNERSTONE OF QUALITY IS PRINTING"

Excellent filling capability and high productivity. In addition to constant printing, motor control of vertical squeegee motions enables digital control at the time of the squeegee's uprising and realizes higher productivity.This head prevents solder overflow to outside the squeegee and solder hanging causes air mixing.

PC board edge support - Stable solder shapes can be printed on the entire board surfaces owing to supporting that far reaches board edges.

EASY OPERATION

Changeover navigation - Display setup procedure can reduce preparation time for production

Easy operation - Printing conditions can be set up automatically by specifying production types

One-touch operation for squeegee replacement - Squeegees can be replaced by one-touch operation

A WIDE RANGE OF APPLICATIONS

Automatic solder supply (option) - Continuous printing for long periods of time is possible with automatic solder supply on stencils

Solder inspection function (option) - Misalignment, bridging, blur and oozing are inspected with the PCB recognition camera.

Inspection result feedback support (option)* - According to the correction data of shifted printing analyzed by solder paste inspection (APC correction data), it corrects printing positions (X,Y,θ)

Mask vacuum support mask-release (option) - Printing mask can be vacuumed during printing and support-table release. It can enable more stable printing by eliminating shift and stick of a mask.

Stencil height detection (option) - Laser processes can optimize a contact of PC boards with stencils so that stable printings can be provided