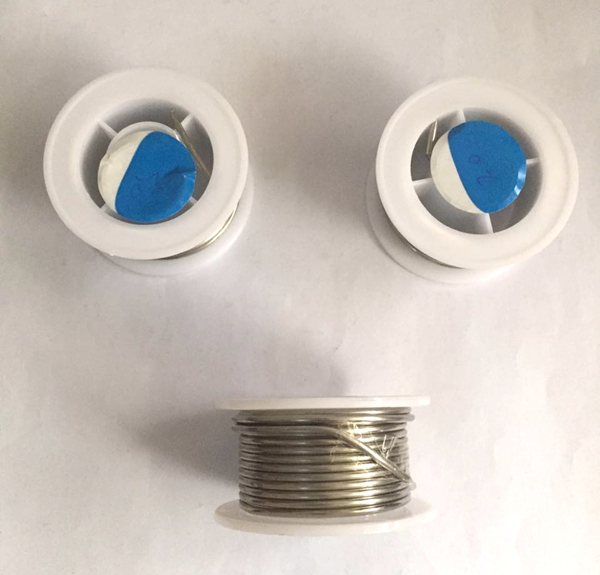

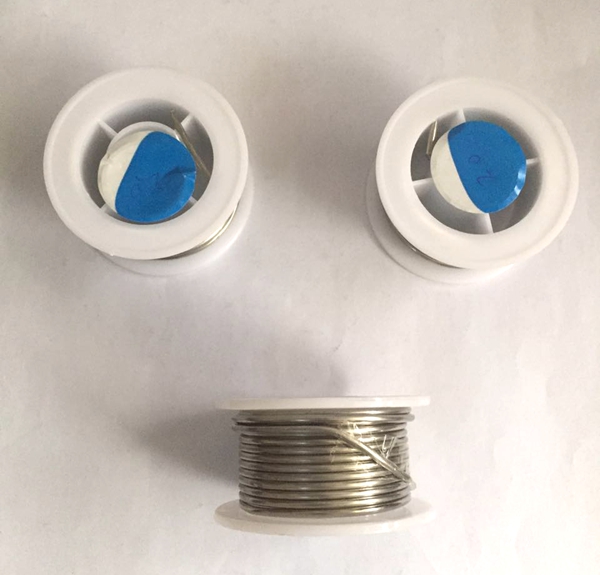

Material: Tin

Diameter: 0.5-3.0mm, 0.3-3.0mm

Melting Point: 227 Degree

Weight: 100/200/500/800/1000g

Application: Soldering Technique

Flux Content: 1.6%~2.5%

Type: tin lead free solder wire

Composition: Sn,Cu

Color:

Silver Grey

Alloy: Sn99.3Cu0.7

Other name: no clean tin lead free solder wire

Lead-free solder compared with traditional lead solder(Sn-Pb),The biggest drawback of Lead-free solder is not good at the infiltrative,and the diffusion rates is also worse than 10%,solder bars are produced by high-purity tin and electrolytic lead, with clean and bright appearance. Good wetting and solderability, under excellent antioxidant, little drosspot produced, with full light spot after dip soldering,The products have good solder results, no adhesion and no corrosive, invasion speed,and satisfy the requirements of rapid welding manual.It is applicable to the high quality electronic products.

lead free solder wire,pb free solder wire features

1. Smooth surface ,Good fluidity, wetting property and bright solder joints

2. Available in many alloy composition

3. Excellent anti-oxidant and lower tin slag

4.Good mechanical properties of solder joints

5.There is a hole in the middle of the solder wire,and with the rosin,which can help the welding

Alloy propotion and usage for solder/soldering wires

| lloy content | Melting point | Rosin content | Wire diameter | Usage |

| Sn63 / Pb37 | 183 | 1.0-3.0 | 0.5mm-3.0mm | Lowest melting point, high tensile strength and shear strength, good wetting, used for high-class electronics products or electrical industry. |

| Sn60 / Pb40 | 183-190 | |||

| Sn55 / Pb45 | 183-203 | Normal electrical or toys field. | ||

| Sn50 / Pb50 | 183-216 | |||

| Sn45 / Pb55 | 183-227 | Cannery, automotive industry, fuse wire, or any other soldering place with low requirements. |