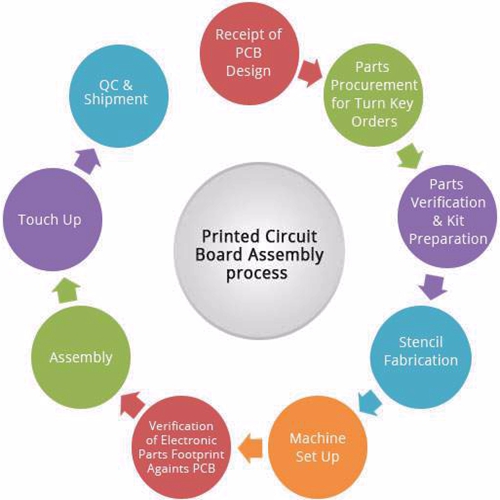

Comprehensively analyzes the distinguish --- SMT Soldering and PCB Assembly Techniques

In Electronics, SMD soldering and SMT Assembly Techniques are different from that of thru-hole soldering techniques. SMD soldering or Surface Mount Technology assembly needs different SMT Equipments and greater experience and expertise.

Surface Mount Circuit Boards have flat tin-lead or gold-plated copper pads without any hole. These traces are called solder pads. Semi-solid solder called solder paste consisting of very fine solder and flux is dispensed on solder pads. Solder paste can be dispensed using stencil with screen printing process with a SMT screen printer.

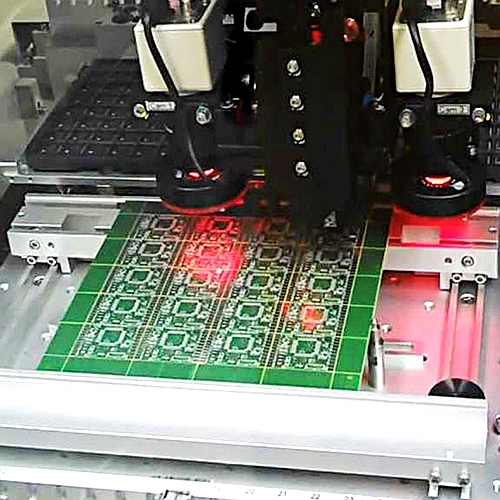

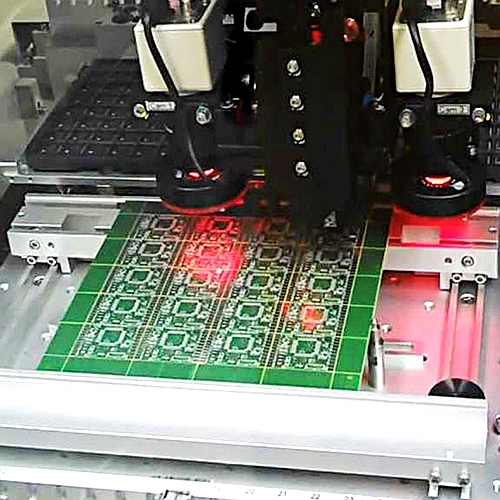

Once the solder paste is dispensed, the circuit board is moved to a conveyor belt of a pick-and-place machine. SMD components are picked up by the pick-and-place machine and placed on the PCB.

Once all the electronic components are placed on the circuit board, it is then SMT Boardconveyed into the reflow soldering oven. The SMT reflow oven has different chambers. The first chamber or zone is called pre-heat zone, where the temperature of the board and all the components is gradually and uniformly raised to prevent and crack to the PCB due to thermal shock. The next zone is high temperature zone where the temperature is high enough to melt solder paste so that the component leads get soldered to the pads on the circuit board. The surface tension of the molten solder keeps the components in place. Surface tension also automatically aligns the components on their pads.

Reflow soldering can be done using different techniques – infrared reflow, hot gas convection or vapor phase reflow with each method having its own advantages and disadvantages.

With double-sided PCBs, the reflow soldering process is repeated using either solder paste or glue to hold the components in place. If glue is used then the parts must be soldered later using a wave soldering process.

Once the soldering process is over, the PCA or the Printed Circuit Assembly need to be washed to remove flux residues and any stray solder balls that could short out closely spaced component leads. Rosin flux can be cleaned with fluorocarbon solvents, high flash point hydrocarbon solvents, or low flash. Water soluble fluxes are removed with deionized water and detergent, followed by an air blast to quickly remove residual water. No-Clean fluxes don’t need any cleaning.

Lastly, the Printed Circuit Assembly is visually inspected for any missing or misaligned components or solder bridging. If any fault is found during inspection, the board is sent for rework. Finally the board is sent for testing to verify that it is working correctly.