What Size Reflow Oven Do You Need?

Many electronic assemblers assume they need a longer reflow oven to meet their throughput requirements and to provide more precise control of their solder profiles, especially if they’re working with lead-free solders. As a result, many manufacturers find themselves spending more money—and sacrificing more floor space—than they really need to.

While long, 8- to 10-zone ovens and faster belt speeds may be the best solution in a high-volume manufacturing environment, our experience shows that, for the vast majority of medium- and lower-volume, high-mix assembly lines common in the U.S (and many other countries), shorter reflow ovens can easily keep pace. In fact, smaller, simpler, and more affordable 4- to 6-zone models are some of our best sellers, and do an outstanding job in handling pick and place throughput, meeting solder paste manufacturers’ reflow specs, and providing reliable, high-quality soldering performance.

But how can you be sure? How much volume can a 4-, 5-, or 6-zone oven handle? A few simple calculations based on data from your solder paste and equipment suppliers will give you a pretty good idea:

Solder Paste Heating Time

The first thing to consider are your solder paste manufacturers’ recommended profiles for the paste formulas you will be using. Solder paste manufacturers generally provide a fairly wide window (in terms of total heating time) for the various stages of the reflow profile — 120 to 240 seconds for preheat and soak, 60 to 120 seconds for reflow/time above liquidous. The average recommended heating times for eutectic and lead-free solders are typically close enough to make any differences negligible for these calculations. Given this range (3 to 5 minutes), we find that an average total heating time of 4 to 4½ minutes (240-270 seconds) is a good, relatively conservative estimate to use.

For this simple calculation, we recommend that you disregard the cooling portion of the solder profiles. Cooling is important, but typically doesn’t affect soldering quality unless the PCB is cooled too quickly. If the PCB is not cooled quickly enough, handling problems may result. These issues may necessitate controlled cooling in higher-volume production environments with larger ovens and faster belt speeds, but again, we find that 4- to 6-zone ovens with passive cooling do a more than adequate job.

Heated Length of Reflow Oven

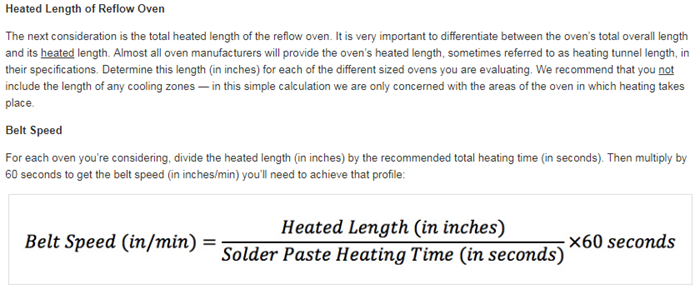

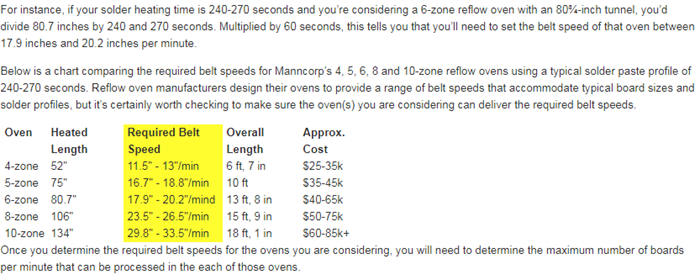

The next consideration is the total heated length of the reflow oven. It is very important to differentiate between the oven’s total overall length and its heated length. Almost all oven manufacturers will provide the oven’s heated length, sometimes referred to as heating tunnel length, in their specifications. Determine this length (in inches) for each of the different sized ovens you are evaluating. We recommend that you not include the length of any cooling zones — in this simple calculation we are only concerned with the areas of the oven in which heating takes place.

Which Reflow Oven Best Fits Your Needs

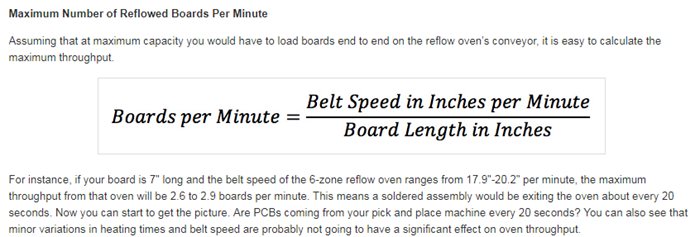

Armed with these numbers, you can start to visualize the relative flow of different products through your SMT factory when using different size ovens. It’s not our intention to over-simplify the oven selection process — this is just a starting point and there are many other things to take into account. For instance, production of double-sided boards may necessitate two separate passes of the same assembly through the oven. Offline processes and manual assembly operations will also affect how much reflow soldering capacity is really needed. If your SMT assembly speeds are very fast, but other processes limit your factory’s throughput, the largest oven in the world isn’t going to do you much good. Another factor to consider is changeover time from one product to another. How much time does it take for oven temperatures to stabilize when changing from one profile to another? There are many different things to consider.

Nevertheless, as we mentioned at the beginning of this post, the majority of our customers usually find, and are often quite surprised, that 5- to 6-zone ovens are more than adequate to handle their needs. Companies will sometimes over-spend on larger ovens in anticipation that higher throughput may be needed in the future. If you fall into this category, keep in mind that smaller ovens use less energy, require less floor space, and their typically lower base price can free up funds that can be put toward options and accessories like nitrogen blanketing, water-chilled cooling, and/or thermal profiling equipment. We have even had customers elect to purchase multiple smaller ovens over a single large oven to give themselves more flexibility for running different temperature profiles simultaneously.

Use these quick calculations to get you in the ballpark. You may indeed find that a larger, 8- or 10-zone, higher-capacity oven is your best answer. We will be happy to supply you with one! Our bet is that if you’re like most of our customers, a 5- or 6-zone will serve you just fine. If, after running through these calculations, you still have questions, contact a joy technology SMT assembly equipment expert.