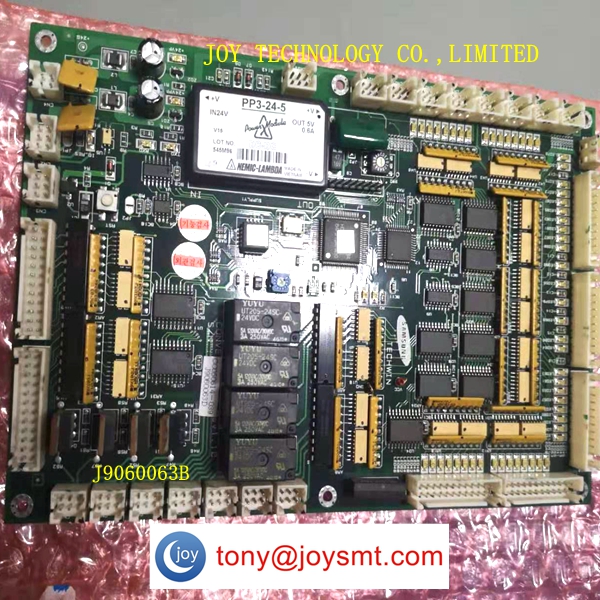

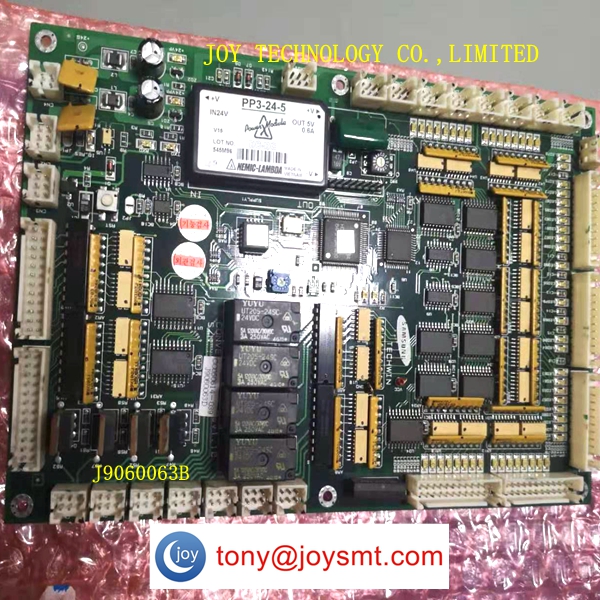

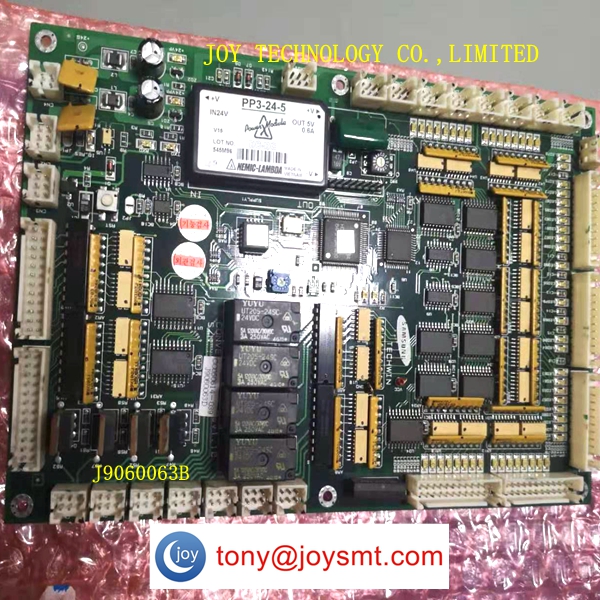

Product description

J9060063B Samsung CP45FV Board Card

JOYSMT Can also supply all kinds of Samsung parts:J1301639 HINGE [E6-10-301-10]

J7252088A SPACER[J7252088A]

J9060102B NEW FIDUCIAL OUTER LED BOARD ASS'Y

J9060141A NEW FIDUCIAL INNEW LED BOARD ASS'Y

J7000787 TAPE GUIDE ASS'Y [TF16S (C/S)]

J70650985B LEVER BKT SHAFT SM1-MF08-048R1

J7065953A STOP PAWL[SM1-MF08-010]

J9065159A SPROCKET 4P ASSY[SM1-MF08-204-1]

J9065239A IDLE GEAR PLATE ASSY[SM1-MF32-028-07]

J7458002A FILTER ELEMENT[LF-M5-60-Z-ELEMENT]

J9055351A NOZZLE CN220 ASSY(CERAMIC)[J9055351A]

J9083180A Z HOME SENSOR CABLE ASSY

J70660113B VINYL ROLLER SHAFT2 SM1-MF12-114R3

J81001725A PSP90-D23-011CPUBOARD PCA-6186-B

J7000833 LINK 2 ASS'Y [TF12S (C/S)]

J7000800 PUSHER LEVER ASS'Y [TF12S (C/S)]

J61081002A HINGE_FRONT_DOOR-STF100N HPBH-4065

J7000786 TAPE GUIDE ASS'Y [TF12S (C/S)]

J81001251A RFEMCS-108-EXHAUST-FAN 108EX*220V

J9060348B FEEDER BASE RIGHT BOARD, NON DOCKING

J9065158A SPROCKET 2P ASSY[SM1-MF08-204]

J9065177B TAPE GUIDE 2P ASSY[SM1-MF08-221]

J2102176-AS MOTOR CABLE ASS'Y [QA2-PW44-2]

J2500322 SPROCKET FIXING SCREW [TF44-024]

J4809051A PBPI-8SA[PBPI-8SA]

J7053686A STOPPER TOP PLATE-R[J7053686A]

J7066048B P-LEVER SPRING 4E[SM1-MF08-133R1]

J7153329A CYL BRACKET-R[J7153329A]

J9060051A DSP BOARD [DSP BOARD REV 1.0]

J9065165A DRAIN LEVER ASSY[SM1-MF08-209]

J9065244A MAIN LEVER ASSY

J9065247A SP SHAFT 24 ASSY[SM1-MF24-002]

J9083109A CONVEYOR DIRECTION CHANGE CABLE ASSY[SM-

J91741084A SM321_HEAD_ILL_BOARD VER 1.6

J91741081A SM321_VISION_IF_BOARD VER 1.2

J91741021A SM330_CONVEYOR_SENSOR_IF_BOARD VER1.0

J9080794A-AS AIR INDICATOR CABLE ASSY[SM-CV026]

J90800114C_AS Z456 MOTOR ENC CABLE ASSY

J90610234D Z4/5/6 MOTOR ENC CABLE ASSY MK-MD12

J90551016A CAMERA_COVER_BOARD_ASSY

J7352003A STOPPER CUSHION[J7352003A]

J7265175A HANDLE(NON IT)[SM1-MF08-150]

J72550021C SILICON TUBE(BLACK ?1?70?1?77?1?77?1?78)

J6602028A FLAT BELT(ENT) [HNB-5E, 1056L, 7W]

J31081004A SERVO_MOTOR_PB

J2500101 LOCKER SHAFT [TF12-067]

J1301168 VACUUM GENERATOR [VGE07F-66]

J90831264B HEAD2_AIR_SOL_PWR_CABLE_ASSY

SAMSUNG FN-14 J7055336A

SAMSUNG FN-08 J7055335A

SAMSUNG FN-05 J7055334A

SAMSUNG AIR TUBE (POLYURETHANE) TU0604B J6713030A

SAMSUNG AIR TUBE UB1065B J6713013A

SAMSUNG AIR TUBE (POLYURETHANE) TU0805B J6713027A

SAMSUNG BALL SPLINE UNIT Z-AXIS J6611008A

SAMSUNG HEX SUPPORT M3x6 J6103028A

SAMSUNG SOCKET SET SCREW M8x10 (SUS) J6010801050

SAMSUNG M3x20MM SCREW J6001302036

SAMSUNG SOCKET HEAD CAP SCREW M3x12 (SUS) J6001301250

SAMSUNG SOCKET HEAD CAP SCREW M3x10 (SUS) J6001301050

SAMSUNG LED PCB D SMD ASSY LED PCB D(SMD TYPE) J4109030A

SAMSUNG LED PCB C SMD ASSY LED PCB C(SMD TYPE) J4109028A

SAMSUNG P-Z34 COMMAND CABLE ASSY MK-VM10-Q J9075977A

SAMSUNG VACUUM SENSOR BOARD ASSY VACUUM BOARD J9060080A

SAMSUNG COMPLIANCE ASSY J9055020A

SAMSUNG COMPLANCE ASSY J9055001A

SAMSUNG PUSHER J7255006A

SAMSUNG CE TRAY COVER(ESD) J7252086A

SAMSUNG ACRYL COVER-REAR(ESD) J7252085A

SAMSUNG CE TRAY COVER(ESD) J7252086A

SAMSUNG ACRYL COVER-REAR(ESD) J7252085A

SAMSUNG CE WINDOW-FRONT(ESD) J7252082A

SAMSUNG ILLUMINATOR SHAFT J7155156C

SAMSUNG C-RING J7055023A

SAMSUNG ROD J7055022A

SAMSUNG CONNECTOR PANNEL J7054101B

SAMSUNG BELT SW-0.7t-1335L J7000875

SAMSUNG BELT SW-0.7t-1240L J7000874

SAMSUNG RELAY LY2N;DC24V J7000856

SAMSUNG 45-MIRROR J6755005B

SAMSUNG NIPPLE SPC8-02 J6619048A

SAMSUNG ANGULAR CONTACT BALL BEARING J6601098A

SAMSUNG STAND-L 0133-628002 J2102276

SAMSUNG CLAMP-CLICK 0133-627014-P1 J2101999

SAMSUNG COIL SPRING D1-301-10-P2 J2101103

SAMSUNG X-AXIS I/F PCB J9800398A

SAMSUNG SUBI/F_PCB J9800395A

SAMSUNG 927NECTOR ASS F/V 6P TO 6P. 50MM J9099138A

SAMSUNG CONNECTOR ASS CP-60.F/V 2P TO 2P. 50MM J9099135A

SAMSUNG MMI MONITOR EXTENDED CABLE ASSY PC04 J9080076A

SAMSUNG INLET WIDTH MOTOR ENCODER EXT CABLE A J9075467A

SAMSUNG FRONT WORK WIDTH SERVO MOTOR ASSY J9075457B

SAMSUNG MOTOR DRIVER CONTROL CABLE 2 J9065025A

SAMSUNG R1 STEP MOTOR CABLE ASSY J9061974B

SAMSUNG X MOTOR X CABLE ASSY MK-MD03CE J9061931B

SAMSUNG I/F BOARD POWER CABLE ASSY MK-HI01CE J9061757A

SAMSUNG CAMERA CABLE #3 VIS-01-3 J9061619A-AS

SAMSUNG CONVEYOR POSITION SENSOR CABLE ASSY CV1 J9061395B

SAMSUNG NEW FIDUCIAL CAMERA ASSY J9059082A

SAMSUNG DOCKING CART BRACKET ASSY-F J9051020A

SAMSUNG GUIDE BRACKET-RR J7157077B

SAMSUNG GUIDE BRACKET-LR J7157075B

SAMSUNG FRONT PLATE HARNESS-HEAD005 J7154101A

SAMSUNG CONVEYOR REAR FRAME J7153107D

SAMSUNG CHIP COVER-MID-T J7052473A

SAMSUNG CHIP COVER-MID-S J7052471A

SAMSUNG CAMERA SUPPORT-M J7051033A

SAMSUNG BALL VALVE BVLC 60-1204 J6719031A

SAMSUNG UNION KAH08-10 J6711162A

SAMSUNG UNION KCE12-00 J6711160A

SAMSUNG TIMING BELT 186-3GT-6 J6602041A

SAMSUNG TIMING BELT 420-2GT-12 J6602040A

SAMSUNG TIMING BELT 216-2GT-4 J6602039A

SAMSUNG LED LAMP APX510-24W J4713013A

SAMSUNG COVER-REAR 0133-628020 J2102287

SAMSUNG I/O DPRAM_PCB J9800390A

SAMSUNG REAR LSO TRIGGER CABLE J9075608B

SAMSUNG FRONT LSO TRIGGER CABLE J9075607B

SAMSUNG HEAD ILL INSULATION PCB J7460003A

SAMSUNG SP880 CLEANING 340x3000mm J7000007

SAMSUNG SP400V SP450V BELT SW-0.7t-1170L J7000846

SAMSUNG SP400V SP450V BELT SW-0.7t-1145L J7000845

SAMSUNG SP400V SP450V BELT SW-0.7t-800L J7000844

SAMSUNG SP400V SP450V ROLL DIA19xDIA70x350L J7000843

SAMSUNG SP400V SP450V BLADE 60x13x4 J7000842

SAMSUNG SP SQUEEGEE BLADE ASSY' SUS304;460x40x0.25 J7000876

SAMSUNG SP SQUEEGEE BLADE ASSY' SUS304;350x40x0.25 J7000862

SAMSUNG SM320 CP63 DRIVER (+.-) KL 207(6). 150mm J8001065A

SAMSUNG SM320 CP63 FITTING KQ2L04-M5/PL4-M5M/SQL04-M5 J1301188

SAMSUNG SM320 CP63 HEX SUPPORT(M3-25) J1201038

SAMSUNG SM320 CP60 CP63 HARD DISK DRIVE R HDS722580VLAT20 J5101021A

SAMSUNG SM320 CP55 CP63 MOUSE PAD - OPTICAL J7452038A

SAMSUNG SM320 CP55 CP63 PLUG PT 3/8 J1301213

SAMSUNG SM320 CP55 CP63 SHOULDER BOLT MSB6.5-10 J1300497

SAMSUNG SM320 CP55 CP63 DISKETT DISKETT 3.5"/1.44M J1201943

SAMSUNG SM320 CP55 CAN HEAD ILL BOARD VER1.0 J9060191A

SAMSUNG SM320 CP55 ELBOW FITTING KQ2L06-02/PL6-02 J1301189

SAMSUNG SM320 CP55 COUPLER (HOLE) HH24 J1300863

SAMSUNG SM320 CP55 COUPLER (CORK) CM24 J1300862

SAMSUNG-SAMSUNG-SM320-CP45NEO-PHOTO-SENSOR--BGS-2S15N-J3212040A

SAMSUNG SM320 CABLE ASSY J9080880A

SAMSUNG-SM320-RIGHT-FDR-SENSOR-INPUT-CABLE-ASSY-SM_FD0-J9080842A

SAMSUNG SM320 LEFT FDR SENSOR INPUT CABLE ASSY SM_FD00 J9080841A

SAMSUNG SM320 RIGHT FDR SOL OUTPUT CABLE ASSY SM_FD004 J9080839A

SAMSUNG SM320 LEFT FDR SOL OUTPUT CABLE ASSY SM_FD003 J9080838A

SAMSUNG SM320 SWING MOTOR CABLE ASSY SM_MD032 J9080829A

SAMSUNG SM320 Z6 MOTOR CABLE ASSY SM_MD031 J9080828A

SAMSUNG SM320 Z6 MOTOR CABLE ASSY SM_MD031 J9080828A

SAMSUNG REEL SPACER TF08-Q125 J7065479B - (0.00)

SAMSUNG FN-14 J7055336A - (0.00)

SAMSUNG FN-08 J7055335A - (0.00)

SAMSUNG FN-05 J7055334A - (0.00)

SAMSUNG AIR TUBE (POLYURETHANE) TU0604B J6713030A - (0.00)

SAMSUNG AIR TUBE (POLYURETHANE) TU0805B J6713027A - (0.00)

SAMSUNG AIR TUBE UB1065B J6713013A - (0.00)

SAMSUNG BALL SPLINE UNIT Z-AXIS J6611008A - (0.00)

SAMSUNG HEX SUPPORT M3x6 J6103028A - (0.00)

SAMSUNG SOCKET SET SCREW M8x10 (SUS) J6010801050 - (0.00)

SAMSUNG M3x20MM SCREW J6001302036 - (0.00)

SAMSUNG SOCKET HEAD CAP SCREW M3x12 (SUS) J6001301250 - (0.00)

SAMSUNG SOCKET HEAD CAP SCREW M3x10 (SUS) J6001301050 - (0.00)

SAMSUNG LED PCB D SMD ASSY LED PCB D(SMD TYPE) J4109030A - (0.00)

SAMSUNG LED PCB C SMD ASSY LED PCB C(SMD TYPE) J4109028A - (0.00)

SAMSUNG P-Z34 COMMAND CABLE ASSY MK-VM10-Q J9075977A - (0.00)

SAMSUNG VACUUM SENSOR BOARD ASSY VACUUM BOARD J9060080A - (0.00)

SAMSUNG COMPLIANCE ASSY J9055020A - (0.00)

SAMSUNG COMPLANCE ASSY J9055001A - (0.00)

SAMSUNG PUSHER J7255006A - (0.00)

SAMSUNG CE TRAY COVER(ESD) J7252086A - (0.00)

SAMSUNG ACRYL COVER-REAR(ESD) J7252085A - (0.00)

SAMSUNG CE WINDOW-FRONT(ESD) J7252082A - (0.00)

SAMSUNG ILLUMINATOR SHAFT J7155156C - (0.00)

SAMSUNG C-RING J7055023A - (0.00)

SAMSUNG ROD J7055022A - (0.00)

JOY TECHNOLOGY CO.,LIMITED Share Samsung machine opearte process as follows,

1 Samsung placement machine operating procedures

1.1 open the air compressor;

1.2 Turn on the wall power switch;

1.3 Remove the dust cover of the machine and open the main power switch (the upper rotary switch, as shown in 2 of Figure 1). The power (POWER) indicator in Figure 2 is on;

1.4 Press the start switch (secondary red and green button switch, the green button is on, the red button is off, as shown in 1 of Figure 1);

1.5 After the computer self-test is finished, enter the operation interface, press the preparation switch (three-level Ready switch, as shown by 2 in Figure 2). This button has the indication function at the same time.

1.6 Warm up 3-4 minutes: Click the shortcut button to display the warm-up operation window, click START, the timer starts to count, after 3-4 minutes, click STOP to stop.

2 Samsung placement machine operating procedures

2.1 Click the shortcut button to open the file dialog box. First select the file type as *.OPT and open the OPT file of the target program. After confirming the error, click OK and the following prompt appears:

TOTAL: X POINT (Total X components)

END OF STEP: CYCLE Y--HEAD Z (ends the Z head of the Y cycle)

Press the YES button to confirm, then the following prompt appears:

LOAD PCB DATA NOW (whether or not the data of the PCB board is loaded)

Press the YES button to confirm, then the following prompt appears:

PUT ALL NOZZLE (put down all nozzles)

Press NO to give up and the target program will finish loading.

2.2 Click the shortcut button to bring up the operation window.

2.3 Press a PCB board in the direction of the board to compare the width on the rail, then turn the handwheel (as shown in Figure 2 in Figure 2) to adjust the rail width until it is suitable. Place the PCB board on the guide rail and push the PCB board back and forth by hand. The board can move freely without falling.

2.4 Put the PCB board ready for the patch into the board, pay attention to the direction of the board.

2.5 Press the START button (as shown by 3 in Figure 2), the status of the machine is changed from IDLE to PAUSE, the patch work head is automatically moved to the waiting position and self-test is performed. After the self-test is completed, the bee The sounder (shown as 7 in Figure 2) emits a "beep", press the START button again, and the machine enters the automatic running state (RUN).

2.6 There are two plates at the same time on the guide rail. When there is one plate in the working position, the plate can be placed at the waiting position of the inlet plate. After the previous board completes the patch, the board will be automatically released, and the board in the waiting position will automatically enter the working position. When the board is completely positioned, a new board can be placed in the board.

Note: When the board in the waiting position has not fully entered the working position, do not put a new board in the inlet. It is necessary to remove the PCB board that has been pasted in time to prevent the next board from coming out and smashing the components on the previous board.

2.7 When a fault occurs during operation, the machine will generate an alarm, the buzzer will continue to emit a “beep-beep---” sound, and the machine enters the FREEZE state. First press the STOP stop button (shown as 4 in Figure 2) to eliminate the alarm sound, then press the RESET reset button (as shown in Figure 2), so that the machine enters the IDLE state, according to the computer prompts to troubleshoot, Click the PREV PCB button on the Run Operation window, the computer prompts whether to continue the previous program, click OK, and then follow the steps in step 2.5.

2.8 When the machine is running, you want to interrupt the operation. Press the STOP button, the machine will enter the PAUSE state. If you want to continue running, press the START button directly. If you press the STOP button and then press the RESET button to put the machine into the IDLE state and want to continue running, click the PLACE CONT button on the Run Operation window, and then follow the steps in step 2.5.

2.9 After the work is completed, first press the STOP button to stop the running state, then press the RESET button to put the machine into the IDLE state, then click the CLOSE button to close the running operation window.

2.10 There are five states in the machine, which are described as follows:

IDLE idle state, yellow, programming, modification procedures, processing problems must be performed in this state;

PAUSE pause state, green, this state will occur when the STOP button is pressed during machine operation or when the START button is pressed in the IDLE state, the program cannot be modified in this state;

RUN running status, green;

FREEZE lock status, red, when the machine has a fault alarm, this state occurs, press the RESET button to return to the IDLE state, and troubleshoot;

WAIT wait state, gray, this state will occur when the controller is used to control the machine reset. After the reset is completed, the machine will automatically return to the IDLE state.

2.11 An abnormal phenomenon occurs during the operation of the machine. Press the emergency stop button (as shown by 6 in Figure 2). After troubleshooting, turn to the direction of the arrow of the emergency stop button, then release, then press the RESET button to cancel the emergency stop state.

3 Samsung Mounter Operating Procedures Controller Description

3.1 speed level adjustment (SPEED LEVEL)

The machine has a total of five working speeds, with five indicators to display the selected level, increasing from bottom to top, the UP button indicates speed increases, and the DN button indicates slower speed.

3.2 Emergency stop (EMG)

When an abnormality occurs during the operation of the machine, press the EMG emergency stop button to immediately power off the machine and stop the operation to prevent the device from burning out.

3.3 Move control keys (A, B, C, D as shown)

Depending on the selected mode, it is possible to control the translation of the head in the front, rear, left and right directions, the rise and fall of the tip, the clockwise counterclockwise rotation of the tip, the zero return of the tip, and the overall return of the head.

3.4 MODE mode selection button

Press this button, press JOG--BANG--HOME--all off-- JOG-...the order indicator lights up in sequence, and the indicator mode of the indicator light is selected.

3.4.1 JOG: fast moving mode, corresponding to the speed level * above two;

3.4.2 BANG: Slow moving mode, corresponding to the following three speed levels;

3.4.3 HOME: Zero return mode.

3.5 AXIS axis selection button

Press this button, press XY--Z/R -- All off -- XY --...... The sequence indicator lights up in sequence, and the indicator light on the indicator light is selected.

3.5.1 XY: The X axis refers to the lateral translation axis, and the Y axis refers to the longitudinal translation axis.

3.5.2 Z/R: The Z axis refers to the rising and falling axes of the tip, and the R axis refers to the clockwise and counterclockwise rotation axis of the tip.

3.5.3 CHK: This function is not available on this machine.

3.6 HEAD Tip Selection Button

Press this button, press the 1--2--3--all-off--1--... sequence indicator lights in sequence, and the indicator light with the indicator light is selected.

1, 2, and 3 correspond to three tips from left to right on the working head.

3.7 Action Description

3.7.1 MODE=JOG (fast) or BANG (slow), AXIS=XY, select the speed grade, then press:

A, indicating that the X-axis moves the working head negatively

B, indicating that the Y axis is moving the working head forward

C, indicating that the X-axis moves the working head forward

D, indicating that the Y-axis moves the working head negatively

3.7.2 MODE=JOG (fast) or BANG (slow), AXIS=Z/R, HEAD=1 (or 2, 3), select the speed grade, then press:

A, indicating that the tip 1 is rotated counterclockwise (or 2, 3)

B, indicating that the Z axis is positively pulled up to the tip 1 (or 2, 3)

C, indicating that the tip 1 (or 2, 3) is rotated clockwise

D, indicating that the Z axis negatively presses the tip 1 (or 2, 3)

3.7.3 MODE=HOME, AXIS=XY, then press:

D (HOME START starts to return to zero), indicating that the work head returns to the zero position

3.7.4 MODE=HOME, AXIS=Z/R, HEAD lights are all off, then press:

D, indicating that the Z and R axes of all the tips are zeroed back.

3.7.5 MODE=HOME, AXIS=Z/R, HEAD select 1 (or 2, 3), then press:

D, indicating that the Z axis and the R axis of the tip 1 (or 2, 3) are zeroed.

To zero the working head XY, the Z/R axes of all the tips must first be zeroed (see 3.7.4) before the working head XY can be zeroed (see 3.7.3). During zero return operation, the machine will enter a short WAIT state after pressing the HOME START button. After the Z/R is zeroed, the machine enters the IDLE state to proceed to the next step.

4 Samsung Mounter Operating Procedures Shutdown

4.1 After the work is completed, click the FILE option on the main menu, select EXIT from the drop-down menu, the computer will prompt:

PUT ALL NOZZLE (put down all nozzles)

Select NO and do not put down the nozzle, the computer then prompts:

EXITS FROM WINDOWS

Select YES to confirm the exit.

4.2 appears on the computer display: IT’S NOW SAFE TO TURN OFF

YOUR COMPUTER

(It is safe to turn off the computer) and directly turn off the upper rotary power switch.

4.3 Turn off the wall power switch.

4.4 Turn off the air compressor.

4.5 Cover the machine dust cover.

5 Samsung SMT Machine Operation Procedures Carefully fill out the “Samsung SMT Machine Work Registration” form

6 Samsung Mounter Operating Instructions Signal Description

There is a signal lighthouse at the top of the machine. The red, orange and green lights are in order from top to bottom. The machine status indicated by each signal is shown in the following table:

7 Samsung Mounter Operating Procedures

7.1 Only trained and qualified operators can operate this machine;

7.2 During the PCB patching process, the operator must not leave the job without authorization;

7.3 During the operation of the machine, the operator's head, hands and other body parts must not reach into the machine; to deal with the fault, first open the door cover and then carry out related processing.