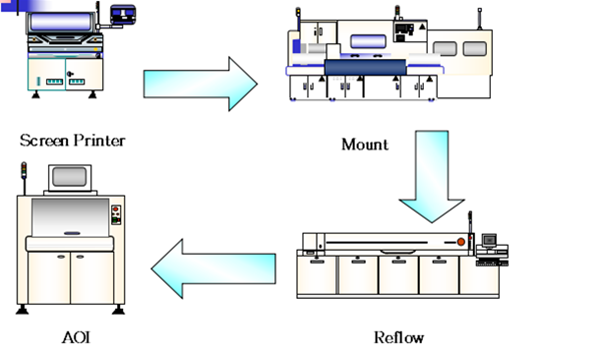

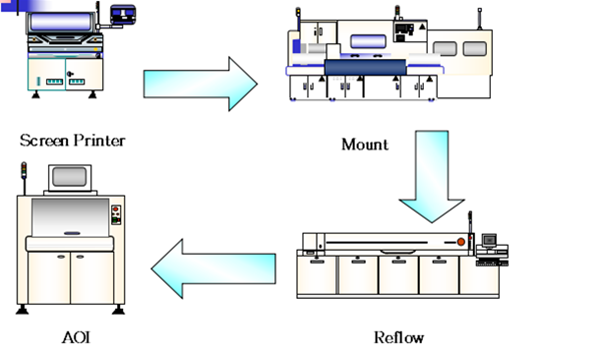

SMT Equipment | SMT Production Line Configuration Solutions | SMT Technology

A solder paste printing machine:

Located in the forefront of the SMT production line, used to print solder paste or plastic patch.

It will solder paste or glue patch correctly printed to the printed circuit board pad or the corresponding position.

HITACHI automatic screen printing machine NP-04LP

Using Windows NT interactive operating system,

Easy to operate, high speed, high precision, good repeat printing

Positioning accuracy of ± 15μm;

Suitable for fine pitch QFP, SOP and other devices for continuous printing

50 × 50mm ≤ printing size ≤ 460 × 360mm

II. Automatic placement machine corresponds to the robot manipulator, the component can be taken out from the pack in accordance with pre-programmed procedures, and paste into the corresponding position on the printed board.

SMT production line placement capabilities and production capacity depends mainly on the function and speed of the placement machine.

1) JUKI KE-2060RM placement machine

With Windows XP operating system, inherits the concept of modularity

The flexibility, versatility, reliability and maintainability;

Optional MNVC camera, a variety of FEEDER, suitable for small cores

Chip (0201), thin chips, QFP, CSP, BGA and other large

Chip mounting

Mounting Speed 12500CPH (Laser), 3400CPH (Image)

Suitable for fine pitch QFP, SOP and other devices for continuous printing;

Patch accuracy of ± 0.05mm (50 × 30mm ≤ mount size

≤330 × 250mm).

2) FUJI high-speed placement machine XP-143

Mounting speed:

21800 chip / h

1600 IC / h

Mounting accuracy:

± 0.05mm (small chip)

± 0.04mm (QFP parts)

IC pin minimum placement pitch: 0.3mm

Component placement range:

From the miniature chip (0.4mm * 0.2mm)

To medium-sized parts (20mm * 25mm)

Reflow machine:

Located behind the SMT machine SMT machine. Its role is to provide a heating environment, the solder paste pre-assigned to the printed circuit board pad melting,

So that the surface mount components and PCB pads through the solder paste alloy to the reliable welding equipment together.

8 temperature lead-free hot air reflow oven

Rail width adjustment range: 50 mm ~ 400mm

Temperature control range: room temperature ~ 300 ℃

Temperature control accuracy: ± 1 ℃

PCB temperature distribution partial: ± 1.5 ℃

Heating time: Approx. 30min

PCB transport mode: chain drive + network drive

Test equipment, its role is to mount a good PCB assembly quality and quality testing of welding.

The equipment has a magnifying glass, a microscope, automatic optical detector (the AOI), in-circuit testers (ICT), X-RAY detection system, functional tester.

V. Rework equipment:

Its role is to detect failed PCB rework repair. Tools used for the iron, rework station and so on.

Six. Cleaning equipment:

Its role is to paste the PCB above the electrical properties of the material or on the body harmful to the welding residues such as flux removed.

Location may not be fixed.

SMT production line auxiliary equipment and technical requirements:

Power supply voltage and power to meet the equipment requirements:

Voltage to be stable, the general requirements of single-phase AC 220 (220 ± 10%, 50 / 60Hz), three-phase AC 380V (220 ± 10%, 50 / 6OHz).

If it fails to meet the requirements, it shall be provided with regulated power supply whose power shall be more than double the power consumption of the equipment.

Mounted machine power requirements of an independent ground, the general should be three-phase five-wire connection method.

Gas source

According to the requirements of the equipment to configure the pressure of gas supply. You can use the factory's gas source, can also be equipped with a separate oil-free compressed air machine. General requirements of pressure greater than 7kg / cm2.

Requires clean, dry clean air.

1) exhaust pipe

Configure the blower according to the equipment requirements. For all hot blast stoves, the minimum required flow rate of the exhaust duct is typically 500 CFM (14.15 m3 / min).

2) cleanliness, temperature, humidity

The workplace should be clean, dust-free, non-corrosive gas.

Ambient temperature of 23 ℃ ± 3 ℃ is the best (printing room temperature to 23 ℃ ± 3 ℃ for the best).

Relative humidity is 45% ~ 70% RH. The initial establishment of awareness of ESD protection in production

As the northern climate is dry, sand blown larger, so the north of the SMT production line requires the use of a double glass factory, the general should be equipped with air conditioning.

3) Electrostatic protection requirements:

(1) The establishment of electrostatic safety workbench, from the workbench, anti-static table mat, wrist strap connector and grounding lines and other components.

(2) anti-static table mat should be more than two wristband connector, one for the operator, one for the technology

Surgeons, inspectors use.

(3) static-safe work bench is not allowed to put their things easy to produce static plastic boxes, rubber, cardboard, glass, drawing data files should be placed in anti-static bag.

(4) an antistatic wrist strap: direct contact of electrostatic sensitive devices must take anti-static wrist strap, wrist strap should have good contact with human skin.

(5) Anti-static container: Shengli bags, turnover box, PCB upper and lower feeding rack, etc. of the production place should have electrostatic protection function. Metal and common containers are not allowed. All containers must be grounded.

(6) Wear ESD clothing: Persons entering the ESD area and touching SMD components must wear ESD clothing, especially in dry environments with relative humidity less than 50% (eg in winter)

Workwear fabrics should be consistent with relevant national standards.

(7) personnel entering the work area must wear anti-static work shoes, wear ordinary shoes, staff should use conductive shoes, anti-static shoe cover or heel strap.

(8) Production line conveyor belt and drive shaft, should be equipped with anti-static grounding brush and strut.

(9) Ionizer static eliminator can be used on the conveyor surface.

(10) The assembly fixture, test fixture, welding tools, various instruments, etc. used in the production site shall be provided with a good grounding line.

(11) Anti-static test bench should be installed at the entrance to the production site. Everyone who enters the production site should conduct anti-static test and enter the site only after passing the test.

During the design of the SMT production line, it should be SMT overall design, and to determine the total number of classes, assembly methods, assembly process, the overall objective of the assembled components.