Intelligent manufacturing under the SMT innovation era

With the implementation of China's western development policy, the western region began to rise. Many of the industry's leading electronics manufacturing companies have been the layout of the western region, China's electronics manufacturing industry to the western region of the trend is accelerating. At the same time, in order to meet the production needs of the next generation of electronic products to meet the market trend of intelligent manufacturing, TCL, Foxconn, Inventec, the new technology and other well-known enterprises in recent years have varying degrees of expansion of the SMT production line, Upgrading of large automated production equipment.

The rapid development of global intelligent manufacturing, the industry on the industry 4.0 or intelligent discussion has also been a few years time. So in terms of SMT smart manufacturing, is it still stay in the theoretical stage? 2017 in Chengdu, held in 2017, "China's western region electronics manufacturing Summit Forum and a step by step new technology seminar", from the advanced assembly system patch solution product marketing manager Mr. Xu Ji will understand the intelligent and program to share The Through the entire production process is broken down into planning, preparation, implementation, optimization of the four steps to analyze the feasibility of each step of the intelligent and bring the corresponding solution.

As of July 1, ASM Pacific Systems, Inc. (ASMPT) acquired DEK from the printing equipment specialist, ASM Assembly Systems has now become the ASMPT SMT Solutions division, with the Print Solutions Division (DEK) and the placement solution (SIPLACE). SMT Solutions is responsible for developing and distributing first-class DEK presses for SMT, semiconductors and solar markets, as well as first-class SIPLACE SMT placement solutions. These two departments will take full advantage of ASMPT development capabilities, to provide customers with an important competitive advantage. By sharing their knowledge and expertise, ASMPT's SMT Solutions division delivers more efficient process integration technology and optimized workflow for global electronics manufacturing companies. In this Chengdu Summit, Advanced Assembly Systems Ltd. will showcase SIPLACE TX, providing high performance and high accuracy with minimal footprint.

The SIPLACE TX placement module sets a new benchmark for mass production. No other placement solution can be in such a small footprint (only 1 meter x 2.3 meters), reaching 25 μm @ 3 sigma accuracy, up to 78,000 cph speed. You can install the new generation of the smallest components (0201 metric = 0.2mm x 0.1mm) for the first time at the same time as other components.

Only 1 meter wide (equivalent to 3.3 feet) single cantilever and double cantilever machine can be flexibly adjusted in the production line. The improved next-generation SIPLACE SpeedStar headset always provides high performance and maximum precision placement. Work with SIPLACE MultiStar and SIPLACE TwinStar to handle the vast majority of components.

The SIPLACE TX placement module is programmed using the SIPLACE Software Suite with matching feeder options and dual rails to support efficient mass production, uninterrupted product switching, and current state-of-the-art production concepts.

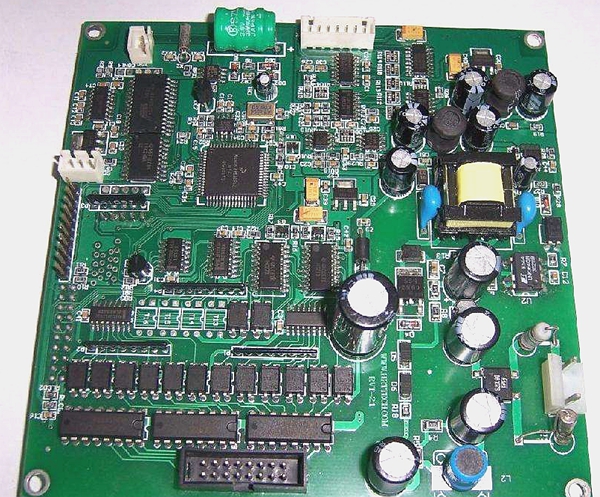

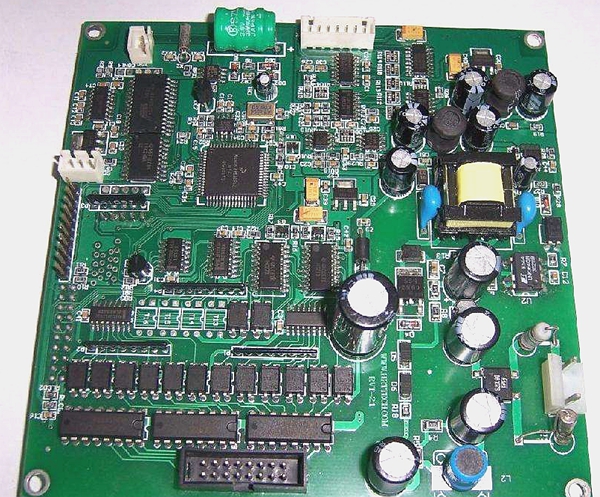

With the miniaturization of electronic products, the size of electronic components continue to shrink, high-density assembly possible, the circuit size than the traditional technology circuit reduced by 30% for the future SMT market growth to bring the main driving force. As one of the most influential international electronic manufacturing exhibitions in Asia, NEPCON will bring together industry experts and world famous brands to bring more information on surface mount, welding and dispensing. Measurement, electronics manufacturing automation, electronic materials, circuit boards and integrated circuits and other topics more than 10 wonderful speech, is expected to have more than 600 professional audience participation.